After part 3, I got some good advice from Joe Herman (thanks, Joe!). He pointed out two things:

- I really don’t want the old shutter in there at all.

- The smooth belt approach will lead to slippage.

He recommended that I use commonly-available GT2 timing pulleys and belts. These have the advantage of not slipping, which is why they are commonly used in CNC machines.

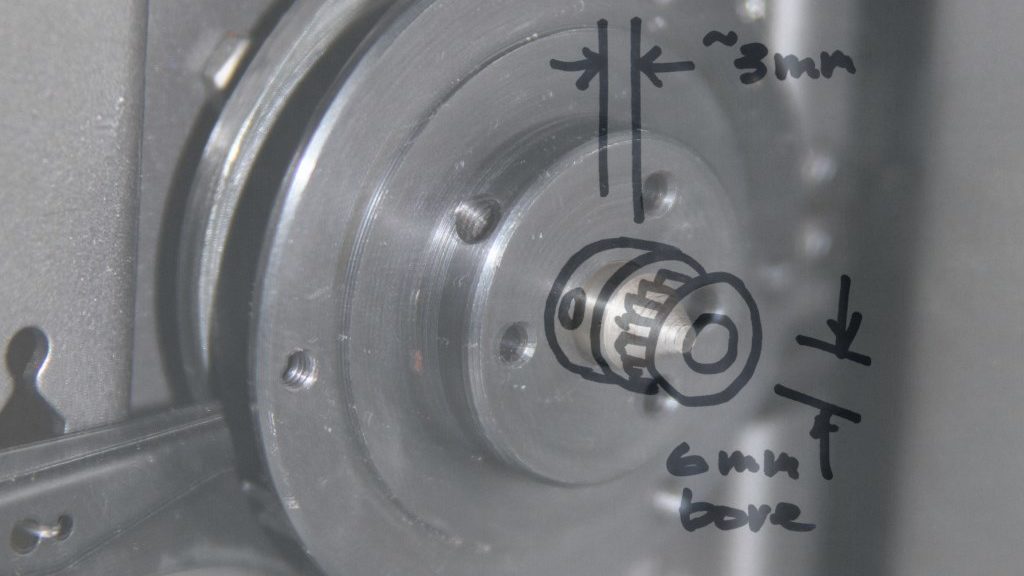

I’m going to give it a try. My biggest concern is the very short segment of the projector shaft that I have to work with — right about 3mm. I will need to file down the end of the pulley in order to allow enough room for the screw to hit the shaft.

Fortunately, the projector shaft is a (relatively) standard bore size. I was able to find matching 5mm (for the NEMA motor shaft) and 6mm (for the projector shaft).

These should arrive later this week.

These should arrive later this week.

My next post will probably be about the success (or failure) of my 3D printed parts for the camera and LED.